When it comes to inventions that sound like science fiction, it doesn’t get more futuristic that 3D printing technology. Whilst 3D printing can sound like little more than a gimmick, its potential to change the world of scientific research is enormous. From bioprinting organs to printing t-shirts that will stop a bullet, the equipment for creating huge scientific advancement has never been so widely available as it is today.

Quick Navigation

Changing Science with 3D Printing

Hardware for the Price of Software

When it comes to setting up a science lab, something that discourages ambitious DIY scientists is the prohibitive cost of equipment. However, these barriers are being broken with the increasing availability of 3D printers, which can create equipment from designs shared online. One of the most popular 3D printers, the RepRap costs less than £1,000 and can reprint more versions of itself. These can then be used to create lab equipment that was previously far too expensive for individual scientists or small labs to purchase.

A centrifuge, for example, is pretty much essential for even the most basic lab experiments, yet to purchase one from the manufacturer can cost more than £10,000. Using a 3D printer and a free design from an open source hardware database, labs can now create several for a fraction of the cost to purchase one.

Scientists are now creating innovative designs for lab equipment that can be sold online and printed out affordably. This will make it possible to equip schools and third world labs with equipment that would never otherwise have been available to them, increasing opportunities for scientific advancement.

Widening availability of 3D printing is also revolutionising the production of prototypes, which used to cost thousands of pounds at each stage of development. Now, a designer who owns a 3D printer can print out prototypes at each stage, discovering what works and what doesn’t, at a small fraction of the cost.

Open source sharing sites allow teams to create new designs built out of printable parts that are available online, or to modify existing designs to achieve a different function. As 3D printing becomes more available, this kind of trial and error design will be possible in schools, in DIY labs, in people’s bedrooms, removing many of the barriers to innovation. 3D printing is likely to change the way we develop products and ideas forever.

Advancing Medical Printing

Bespoke Cells and Organs

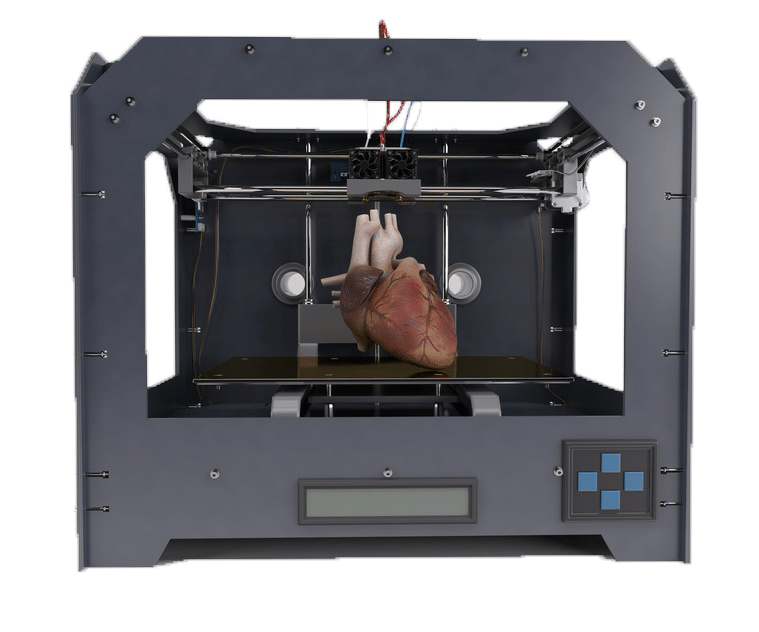

Some of the most exciting advancements in 3D printing are happening in the field of bioprinting. Scientists have successfully created 3D-printed liver cells that are able to function for more than 40 days. Whilst these cells are currently being used to test new pharmaceuticals, the advancement suggests we are on target to achieve 3D-printed organs within the decade, as experts predict.

In addition to liver cells, scientists have also successfully printed sheets of cardiac tissue and stem cells that can reproduce different kinds of human tissue. Similarly, a prototype for bioprinting cartilage has already been created, suggesting we are mere years away from being able to replace everything from an ear to an entire heart.

Surgical Tools

Bioengineering scientists have also had success in designing and 3D printing surgical tools, and other medical equipment. Bioengineering students from the University of British Columbia, for example, won a prestigious prize for a 3D-printed surgical smoke extractor they had designed. More basic tools, such as forceps and clamps, can also be 3D printed, with the added advantage of coming out of the printer sterile and costing just one tenth of their stainless steel equivalents.

Patch Repairs

As well as printing the tools for surgery, advancements in 3D printing are moving towards also providing the materials. Human cell heart patches, to repair heart tissue, have successfully been tested on rats. Additionally, artificial cardiac tissue that mimics the mechanical and biological properties of the human heart have also been successfully tested at this level. This use of 3D printing provides the hope of enormous medical advancement in the near future.

3D Printing: What Next?

Eliminating Organ Donors

One of the most exciting future possibilities of the medical advancements in 3D bioprinting is a world without organ donors. Researchers suggest we are likely to see the technology for printing complete workable organs within the next 10 years. This would mean that people who require lifesaving organ transplants will no longer have to wait for a suitable donor. Instead, the required organ will simply be printed out to meet their specifications.

With huge advancements being made in the development of artificial tissue, these organs could be tailored to match their recipient biologically, preventing the body from rejecting the new organ. This will be a major milestone in modern medicine’s ability to treat illnesses and save lives.

Innovative Materials

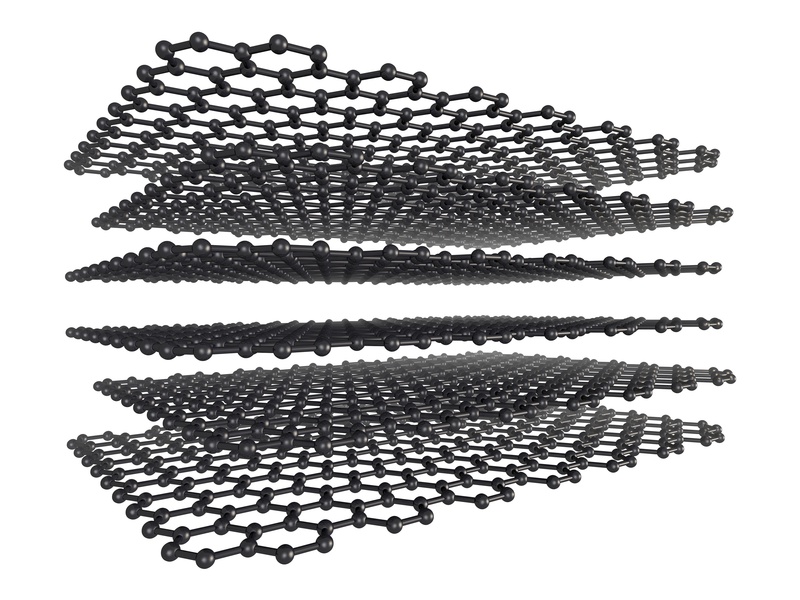

From human stem cells to graphene, a substance 100 times stronger than steel, the materials that are suitable for 3D printing are becoming more diverse. Combining these innovative materials with 3D printing technology opens up the possibility of creating products beyond our wildest imagination.

Take graphene, for example, which is incredibly strong, but also flexible and transparent. Using 3D printing technology, it could be possible to create a bulletproof graphene outfit for professions such as the police which perfectly fits its wearer’s body.

Beyond simply printing customised organs, it may be possible in the future to create biological materials which release medication over time, directly targeting the problem area. Uses for these kinds of materials, combined with 3D-printed technology are infinite, and they have the potential to completely change the world as we know it.

InterFocus is a leading team of research suite suppliers and fitters. If you want more information about redesigning or fitting a laboratory, visit our homepage or call us on 01223 894 833.