Climate control is an issue affecting every person on the planet, and every industry has a responsibility to increase their sustainability and improve their energy efficiency. Intelligent changes now could dramatically improve the planet’s fortunes in the coming years, decades and centuries.

Research laboratories and science suites found in educational institutions are no different, possessing the same sustainability responsibilities. Here we look at the global movement towards greater sustainability, and the role the modern lab can play. We’ve answered a number of pertinent questions, so you can navigate to the question that most interests you by using the links below.

Why Must Labs Be Made More Sustainable?

Covering the Cost of Sustainability

Why Must Labs Be Made More Sustainable?

At the 2015 United Nations Climate Change Conference in Paris, 195 countries committed to a legally-binding global climate deal which pledged to limit global warming to 2°C above pre-industrial levels. In response to this agreement, the Higher Education Funding Council for England has set the ambitious goal of reducing carbon emissions in the sector by 2020, when the deal comes into force. This has led the higher education sector to lead the way in developing sustainable laboratories, as labs often account for a significant amount of a university’s carbon emissions.

A typical laboratory uses as much as five times the energy and water per square foot that a standard office building does, with some labs using up to 10 times the standard level. This is because laboratories have a large number of containment and exhaust devices, a lot of heat-generating equipment, and require uninterrupted power supplies to preserve irreplaceable experiments in emergency situations.

Laboratories operating outside of higher education, whilst not bound to such stringent targets, still have their own sustainability goals to reach. No matter what industry labs belong to, some work is likely needed to ensure the scientific community is working towards the fulfilment of the Paris Agreement. A holistic approach is required to identify how laboratories can become more sustainable, from rethinking initial design to retrofitting existing labs with more sustainable equipment.

Sustainable Through Design

Architects and designers who build laboratories are beginning to concentrate on environmental sustainability, harnessing natural heat and light to create efficiencies. From choosing the right windows to the colour of the roof, there are a variety of ways that building design can reduce the environmental impact of a laboratory. Using natural light and heat is becoming an important part of lab design, with large, well-insulted windows reducing the need for fluorescent bulbs and boilers wherever possible.

Using light-coloured roofing tiles with a coating which reflects light and heat has also been shown to help reduce energy usage. Equally important is ensuring that plumbing and wiring are both properly sealed where it enters the building, as air leakage is a significant source of energy waste in many buildings. Integrating photovoltaic panels is also a great way of integrating green technology into the design of a lab, as they can be used both as building materials and to generate electricity. By keeping sustainability in mind during the design and construction stages of a laboratory, it is possible to significantly reduce both carbon footprint and running costs even before any other efficiencies have been made.

Sustainable from Day One

Maximising energy efficiency isn’t just a box-ticking exercise challenging individuals and businesses to identify a set number of ways to cut energy use – it should be a practice woven into every aspect of life. Designing, manufacturing and installing a laboratory or research suite should be no different, with efforts made to increase energy efficiency at every opportunity.

When sub-contracting work to contractors and third-parties, ask them to demonstrate their energy efficiency credentials before partnering with them – and then exclusively employ the most energy efficient organisations.

For businesses truly dedicated to achieving the highest levels of energy efficiency, we’d recommend employing the assistance of professionals. Either bring a consultant in house or agree a deal with a specialist firm, and utilise their expertise throughout the process. This will guarantee your business receives the input of experienced professionals, identifying energy efficient processes you may never have thought of.

Keeping a consultant or firm on your side throughout the process from initial design to ribbon-cutting will ensure that all short-term and long-term energy efficiency opportunities are identified and fulfilled.

The Benefits of Going Bespoke

This leads us on to the benefits of seeking a bespoke design for your laboratory. Choosing an off-the-shelf model may make the decision-making process a little simpler and could keep the initial costs down – but it could also mean you’re passing over energy efficiency opportunities.

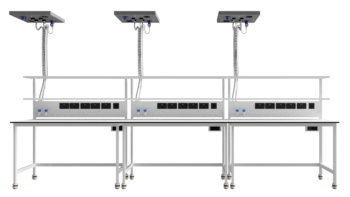

Opting for a bespoke design, in partnership with a specialist manufacturer, could open you up to a huge array of opportunities to make money-saving and environmentally-friendly decisions. Vetting your lab design and manufacturing partners to find the organisation with the greatest energy efficiency credentials could guarantee the greatest cost-cutting process.

Improving Existing Labs

For labs which haven’t been designed with sustainability in mind, it is still possible to retrofit existing labs to increase their efficiency and reduce emissions. Sharing lab equipment and other facilities is also an effective way to reduce a lab’s carbon footprint, with some universities consolidating different disciplines into one shared laboratory space. Lots of universities are undertaking impressive sustainability initiatives in a bid to improve the sustainability of their lab facilities, with great success.

Even simple changes can make a big difference to a lab’s sustainability, such as turning off equipment when it isn’t in use or using preservative for reagents that do not require cold temperatures for storage. Ensuring that the sashes are kept closed on fume hoods when they are not in use can make significant energy savings, with each fume using around £3,000 of energy each year.

There are a number of investments which can be made which will offer long-term savings and greater energy efficiency. From structural changes to the laboratory, including added insulations and improved glazing, to the implementation of equipment specifically designed to offer greater energy efficiency; intelligent changes can offer great benefits.

Installing a heat pump is also a good way for a laboratory to reduce its carbon emissions. Where typical boilers maximise efficiency at 90%, a heat pump can achieve as much as 500% efficiencies depending on the system and conditions. As demand for sustainable lab technology increases it is likely that innovation in this area will continue to flourish, offering an even wider range of solutions.

Covering The Cost of Sustainability

Meeting sustainability targets is important, but both building and equipping labs in order to maximise efficiency can be a daunting financial task. As a long-term investment, however, creating energy efficiency is often a financially sound decision.

For example, Reading University’s estate-wide upgrade of science laboratory fume cupboard ventilation cost £768,000 to deliver and generated predicted annual savings of £223,958. The system is predicted to pay for itself within three years of installation, delivering both financial and energy efficiency savings thereafter. Some sustainability initiatives, however, can present a long-term financial cost, so it is wise to consider expenditure when deciding how to make your laboratory more sustainable.

InterFocus is a leading manufacturer and supplier of research and commercial laboratory fit out solutions. For more information about how we could help you, visit our homepage or give us a call on 01223 894833.